| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : ZTRFM

Model Number : ZTAC

Certification : CE

Place of Origin : China

MOQ : 1 set

Price : 80000

Payment Terms : L/C, T/T

Supply Ability : 30 sets per month

Delivery Time : 90 working days

Packaging Details : Nude with anti-oil package

Usage : Roll Forming

Control method : PLC

Productivity : 8 to 10 minutes

Sheet Cutting Length : Adjustable

Machine Basic Frame : 500# H steel welded

Shaft Diameter : 80mm

Automatic : Fully automatic

Forming Stations : 22

Electricity : customize

Product_After-Sales Service : Engineers available to service machinery overseas

Shaft : 45# steel with tempering

Metal Supermarket Shelf Back Panel Profile Making Machine

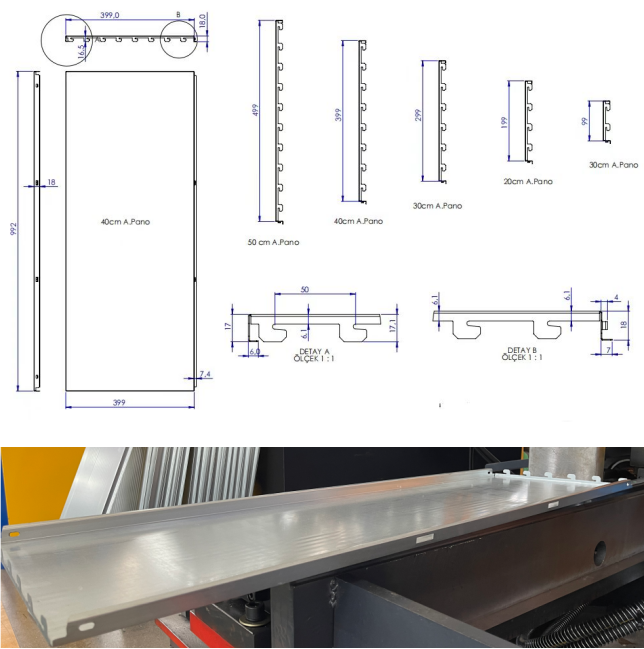

Metal Supermarket Shelf Back Panel Profile Making Machine is designed to make the metal shelf panel either with punching, embossing type or flat type. Standard supermarket shelves are specially developed and designed for standard supermarkets, with the biggest features of being lightweight and beautiful. They do not have the complex types of accessories like those in large supermarkets, and have also been adjusted in display methods, paying more attention to the display effect and humanized display of products. Its main customers are local chain medium-sized supermarkets. Take the following drawing profile for example to show you how the machine is designed:

Metal Supermarket Shelf Back Panel Profile Making Machine:

Metal Supermarket Shelf Back Panel Profile Making Machine working flow:

The process flow of the production line: 5T hydraulic tensioning belt trolley material rack → 700 leveling machine → a total of 3 stations, including 1 station for punching small holes on the left and right, another station for punching and arranging holes, and 1 station for punching notches and hanging ears (5 sets of molds with different forming widths need to be replaced by the corresponding molds) → CNC 1.3kw servo feeding → 20 sets (rolling forming width adjustable) → servo tracking hydraulic cutting and flanging (1 set of combined molds) → discharge conveyor.

| Item | Specification | |

| Material | Material | Q235 |

| Machine specification | Thickness | 0.5-0.6mm |

| Coil inner | Inner diameter of 450~500mm, outer diameter of 1200mm | |

| Working speed | 8-10m/min equipment working line speed | |

| Machining length | according to requirements | |

| Machining accuracy | L<1000mm:±0.5mm | |

| Forming Width | 99mm 199mm 299mm 399mm 499mm | |

| Forming section | on drawing | |

| Power | total power | ≤30KM |

The Metal Supermarket Shelf Back Panel Profile Making Machine is composed by the following elements:

As to the decoiler, you can choose the manual one or hydraulic one 5ton or 10 ton.

As to the before punching part, the width is adjustable, here we can add different types of embossing. And if you like punching holes, here we can add one more punching.

As to the main rolling forming machine, we designed with double arch frame with gearbox inside, to make sure the transmission smoothly. And PLC control for the sizes changing. And also designed with the adjusting mark. Servo motor transmission. By those designs ,we can make sure the machine working stable and accurate.

As to the shearing and bending, with the adjustable bending molds. More accurate light switch sensor.

As to the PLC control system:

1. Adopting programmable Mitsubishi PLC; Adopting Huichuan servo control, adopting sine frequency converter speed regulation centralized automatic control, and using Japanese Izumi relay.

2. The entire production line adopts centralized automatic control, with linkage between the molding machine and the hydraulic press.

3. Alarm function: It has alarm functions such as material shortage shutdown, counting, production reaching shutdown, emergency stop, mold jamming, limit, etc.

Metal Supermarket Shelf Back Panel Profile Making Machine working videos for your reference:

|

|

Metal Supermarket Shelf Back Panel Profile Making Machine Images |