| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Model Number : floor decking Machine

Certification : CE

MOQ : 1 set

Price : on discuss

Payment Terms : T/T, L/C, Western Union

Supply Ability : 20 sets per month

Delivery Time : 30 days after receiving deposit

Packaging Details : the Packaging Detail of roll forming machine door : Standard and safe export package, suitable for long term sea way shipping Delivery Detail: within 45 working days after down payment received

Model NO. : EN-130JK

Material Thickness : 0.4-0.7mm

Rolling Speed : 6-15m/Min

Roller Stations : 14 Stations

Hydraulic Cutting Power : 5.5kw

Material of Shaft : 45 Steel

Transport Package : Plastic Film, Container

HS Code : 845522100

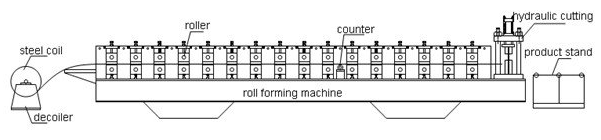

Working flow

| NO. | Description | Quantity (set) | Remark |

| 1 | 5Tmanual decoiler | 1 | As one complete part |

| 2 | Guiding device | 1 | |

| 3 | Pre-cutter | 1 | |

| 4 | Forming system | 1 | |

| 5 | Transmission system | 1 | |

| 6 | Hydraulic guillotine | 2 | |

| 7 | Support table | 2 | |

| 8 | Hydraulic station | 1 | |

| 9 | Control box | 1 | |

| 10 | Spare parts and tools | 1 | As attaching list |

roll forming

| No. | Spc. | |

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | 410mm |

| 3 | Rollers | 15rows |

| 4 | Main power | 4kw |

| 5 | Hydraulic | 5kw |

| 6 | Thickness of the plate | 0.3-0.6mm |

| 7 | Productivity | 8-10m/min |

| 8 | Diameter of the roller | Φ70mm |

| 9 | Roller material | 45# steel polished and coated with chrome HRC55-60° |

| 10 | Shaft material | high grade No.45 steel after treatment |

| 12 | Blade material | Cr12 steel after treatment |

| 13 | Voltage | 380V 50Hz 3phases |

| 14 | Hydraulic | 40# |

| 15 | Processing precision | Within 2.00mm |

| 16 | Control system | PLC Frequency Control System with touch screen |

Cutting

(1)Material for Cut-Off Modular:Cr12 steel after treatment

(2)Hardness for Heat Treatment:HRC55 – 60°

(3)Cut-Off Type: Hydraulic, Automatic Cut-Off

(4) Motor for Hydraulic Stand: 3 kw

PLC

| Main item | Parameter detail |

| PLC | Delta(standard) or according to your request |

| Inverter | China brand(standard) or according to your request |

| Touch screen | Mcgs(standard) or according to your request |

| Encoder | China brand(standard) or according to your request |

| Voltage/HZ/Phase | 380v/50-60hz/3phase |

Hydraulic pump

| Main Item | Parameter detail |

| Motor | 3kw China brand or according to your request |

| Pump | China brand or according to your request |

| Solenoid valve | China brand or according to your request |

| Cooling system | Cooling fan |

AQ

1) Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2)Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly

|

|

0.7mm Roofing 8m/Min - 12m/Min Corrugated Iron Sheet Making Machine Images |